Friction, an omnipresent force in the physical world, governs the interactions between surfaces and plays a pivotal role in everyday life. This exploration delves into the multifaceted nature of friction, its various types, underlying principles, and practical applications that range from industrial engineering to the simple act of walking.

Definition and Types of Friction:

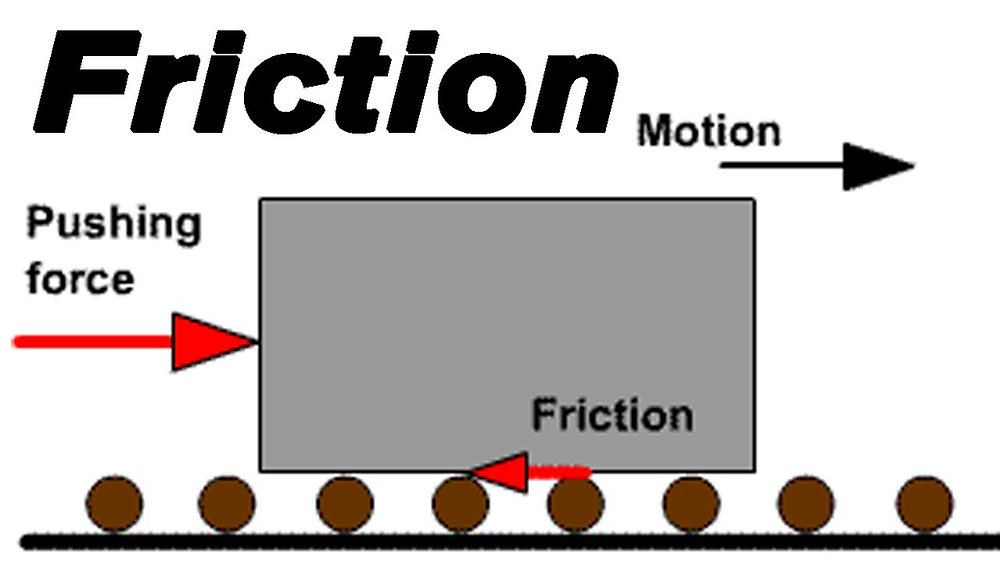

Definition: Friction is a force that resists the relative motion or tendency of such motion between two surfaces in contact. It arises from the interactions between atoms and molecules at the microscopic level.

Types of Friction:

Static Friction: Acts on objects at rest, preventing them from initiating motion.

Kinetic (Dynamic) Friction: Opposes the motion of objects already in motion.

Rolling Friction: Occurs when one object rolls over another, such as a wheel on a surface.

Fluid Friction: This applies to objects moving through fluids like air or water.

Principles of Friction:

Surface Roughness: Friction is influenced by the roughness of surfaces in contact. Microscopic irregularities create contact points that resist motion, contributing to both static and kinetic friction.

Normal Force: The normal force, exerted perpendicular to the surfaces in contact, plays a crucial role in determining the magnitude of friction. It varies with the weight of the object and the angle of the surfaces.

Coefficient of Friction: The coefficient of friction quantifies the level of friction between two materials. It is the ratio of the force of friction to the normal force and is specific to the materials in contact.

Applications of Friction:

Industrial Engineering: Understanding and managing friction is crucial in industrial settings. Engineers optimize surfaces and lubricants to reduce friction, enhance efficiency, and prolong the lifespan of machinery.

Automotive Braking Systems: Friction plays a critical role in automotive safety. Brake systems rely on the friction between brake pads and rotors to decelerate the vehicle. Anti-lock braking systems (ABS) manage and optimize this friction to prevent skidding.

Traction in Transportation: Friction is essential for traction in transportation. The friction between tires and roads allows vehicles to move forward efficiently. On icy surfaces, the lack of friction can lead to reduced traction and potential accidents.

Factors Influencing Friction:

Nature of Materials: Different materials exhibit varying levels of friction. Smooth surfaces generally experience less friction than rough surfaces. The nature of the materials in contact, including their composition and texture, affects friction.

Applied Force: The force applied to an object influences the friction it experiences. Increasing the applied force generally increases the force of friction. This relationship is described by Amontons’ laws of friction.

Overcoming Friction:

Lubrication: Lubricants, such as oils and greases, are used to reduce friction by creating a thin film between surfaces. This minimizes direct contact between rough surfaces, allowing for smoother motion.

Ball Bearings: In mechanical systems, ball bearings are employed to reduce friction. The rolling action of the bearings minimizes the contact points between surfaces, significantly decreasing friction and wear.

Challenges Posed by Friction:

Energy Loss: Friction results in energy loss as mechanical energy is converted into heat. This phenomenon is evident in various applications, from the heating of car brakes during deceleration to the warming of hands when rubbing them together.

Wear and Tear: Friction contributes to wear and tear on materials and surfaces. In machinery, this can lead to the degradation of components over time, necessitating maintenance and replacement.

Research and Innovations in Friction:

Nanotribology: At the nanoscale, the study of friction, known as nanotribology, explores the behavior of materials and surfaces. Understanding friction at this level is crucial for advancing nanotechnology and developing more efficient materials.

Superlubricity: Superlubricity is a state where friction is extremely low or almost nonexistent. Researchers are exploring ways to achieve superlubricity, which could revolutionize various industries by minimizing energy loss and extending the lifespan of moving parts.

Teaching and Understanding Friction:

Educational Demonstrations: Demonstrations and experiments are commonly used to teach the principles of friction in educational settings. These may include activities such as sliding objects on different surfaces, measuring coefficients of friction, and exploring the impact of lubricants.

Simulation Software: Advances in technology have led to the development of simulation software that allows students and researchers to model and analyze friction in virtual environments. These tools enhance understanding and facilitate experimentation in a controlled setting.

Friction is a fundamental force that shapes our physical interactions with the world. From the simple act of walking to the intricate workings of machinery, the principles of friction influence various aspects of our daily lives.

While it presents challenges, it also offers opportunities for innovation and improvement in diverse fields. As our understanding of friction deepens through research and technological advancements, the potential to harness and manipulate this force opens doors to new possibilities in engineering, materials science, and beyond.